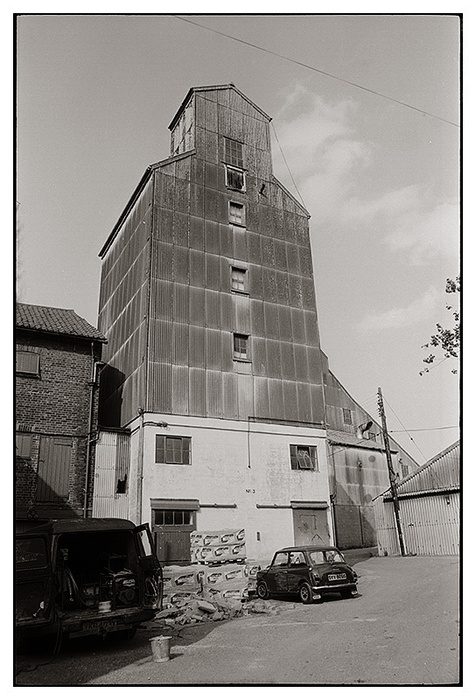

The Kings Seeds Silo

was a fixed part of the townscape for many of us – this is its story.

The silo was built in March 1937 by Turners of Colchester and was quoted at £3,875, although the the final cost was a bit higher at £4,089. Kings issued 3,000 shares to pay for it. The firm needed more storage because of an increasing demand for corn and the new silo and warehouse provided a capacity for 1,450 quarters of grain*. The silo was in its time quite revolutionary and was one of the first to be built in the UK. At the time Kings were phasing out its seed trade for private gardens to concentrate on cereals and other farm and market garden seeds.

showing how the silo dominated the centre of the town.

pitch pine storage bins and the wooden structure were exposed.

Underneath its asbestos cladding the building was much more exotic. There was a very substantial concrete substructure but most of the building was timber and this was exposed when the building was being demolished. Each floor was made up of rectangular storage bins made of expensive pitch pine. In the centre of one face of the building, windows lit a stairway which gave access to the floors and the machinery at the top.

Grain Elevator. Also visible in the photo are two ‘tramlines’ running from top to bottom of the building which indicate where a grain elevator lifted grain from a pit in the basement of the building to a dispersal area at the top where shutters could be opened and closed to allow it to be sent down to any of the bins below. The elevator itself was a continuous canvas belt with steel cups attached which scooped up the grain and tipped it out at the top as the belt started its downward journey. The sound of it running; ‘swish swish swish’ could be heard from inside the building whenever it was at work.

The grain was sold for seed and the silo allowed for many varieties to be separately stored and retrieved as required. In those days, grain was carried about in sacks – sacks of wheat contained 2 hundredweight and those of barley 2¼ hundredweight (101kgs and 114kgs) the difference is because grain was measured in volume rather than weight. These very heavy sacks were moved around by hand.

As the grain arrived from the farms the sacks were opened and tipped into a pit and sent via the elevator to one of the bins and stored. When it was needed, the grain would be retrieved, cleaned and dressed before being sacked up again and taken by lorry to the farms for sowing.

Dressing the seed involved treating it with with chemicals in the form of a powder - especially a fungicide which protected it from the then common ‘loose smut’ a deadly disease of wheat. Loose smut disease was carried through from one year to another in the seed grain and could be the ruin of a farm. Kings were able to guarantee that their seed was free of the disease giving their grain a premium price. Other seed treatments were also offered.

In World War II the silo was thought to have been an easy and valuable target for enemy planes so on 14th November 1940 the firm of Everetts were engaged to paint it in camouflage at a cost of £35. Many, I am sure, can still remember the faded patches of green and brown which adorned it but by the late 1960’s the colour had all but disappeared.

The silo was demolished in 1989-1990 after J K King had moved to Purley Farm and the 'Kings Acre' site, which is actually about 3 acres, was redeveloped for housing.

* A quarter is a measure of volume and is equal to 8 bushels and a bushel is about 8 gallons or 36.4 litres so the silo's 1,450 quarters is the quivalent of 92,800 gallons or 422,240 litres capacity.(Thanks to Peter Miller)

Sources

Thanks are due to Francis Nicholls who supplied much of the information above.

‘Seedtime’ by Elinor M C Roper, Phillimore, 1989 is a great book on Essex seed-growing and includes chapters on JK King and EW King.

Comments

By Roddy Miller: Hi Trevor notes on the Silo!

Lorries would back up to the silo which had a pit just inside the doorway This was Jack Bowers domain The men would manually off load 2-and-a-quarter Hundred weight sacks on their backs to the pit and shoot the grain It would take four men working hard about two hours to do a load My old man was doing this and a rat came out of the sack in the grate pit Dad tried to stamp on it but he missed and the rat ran up his trouser leg Dad tried to smite it missed and thumped himself hard in the groin Pain ! The rat then bit him high in the groin and off he had to go for tetnus jabs He was actually quite sick from this episode In the silo often racing pigeons which had got lost would roost up in the top as windows were always open I often caught these John Moyce was washing his lorry right under the silo and I shot a starling which was perched on the top gutter Down it came and I had to yell and warn John as it fell and just missed him He was not happy! Many of the men who worked on the dressing of seeds suffered later in life from various lung issues and the like elf-n-saftey was not considered too much then.

By Roddy Miller: Hi Trevor notes on the Silo!

Lorries would back up to the silo which had a pit just inside the doorway This was Jack Bowers domain The men would manually off load 2-and-a-quarter Hundred weight sacks on their backs to the pit and shoot the grain It would take four men working hard about two hours to do a load My old man was doing this and a rat came out of the sack in the grate pit Dad tried to stamp on it but he missed and the rat ran up his trouser leg Dad tried to smite it missed and thumped himself hard in the groin Pain ! The rat then bit him high in the groin and off he had to go for tetnus jabs He was actually quite sick from this episode In the silo often racing pigeons which had got lost would roost up in the top as windows were always open I often caught these John Moyce was washing his lorry right under the silo and I shot a starling which was perched on the top gutter Down it came and I had to yell and warn John as it fell and just missed him He was not happy! Many of the men who worked on the dressing of seeds suffered later in life from various lung issues and the like elf-n-saftey was not considered too much then. By John Wicks: I remember this well. It was my playground. Grandparents lived in Orchard Cottage and grandfather Isaac Potter worked for Kings.

I used to climb the very steep steps to the top of the silo and observe the grain dispensers at work.

In another building was a pea grading machine that never stopped and needed constant attention. There was a sack hoist in another warehouse lifting sacks to the higher floors.

At

Near the cottage was a small science lab and opposite a large caged area for plant testing which kept the birds out; almost. I enjoyed many years visiting the cottage regularly and often slept there during the war. Now 85.

By John Wicks: I remember this well. It was my playground. Grandparents lived in Orchard Cottage and grandfather Isaac Potter worked for Kings.

I used to climb the very steep steps to the top of the silo and observe the grain dispensers at work.

In another building was a pea grading machine that never stopped and needed constant attention. There was a sack hoist in another warehouse lifting sacks to the higher floors.

At

Near the cottage was a small science lab and opposite a large caged area for plant testing which kept the birds out; almost. I enjoyed many years visiting the cottage regularly and often slept there during the war. Now 85.